CNCTOPBAOS 4 Axis Offline Stand Alone CNC Motion Controller System DDCSV3.1,Servo/Stepper Motor Control Replace Mach3 PLC+100PPR MPG Handwheel with E-Stop for CNC Router Engraving Machine

$295.00

Price: $295.00

(as of Jun 16, 2024 03:55:30 UTC – Details)

Product Description

DDCSV3.1 Offline Standalone Motion Controller

Package include:

1 x 4 Axis CNC Offline Stand alone Controller DDCSV3.11 x 4 Axis 100 Pulse Pendant Handwheel MPG with Emergency Stop with 15-pin plug1 x 4GB USB Flash drive1 x USB Extension Cable+AccessoriesPdf. user manual (If you have not received the user manual at Amazon Message Center from us,please message us)

Introduction

Aims to combine high quality and high reliability with affordability. The DDCS is a 4 axis motion controller for stepper and servo systems. DDCS V3.1 is updated from DDCS V2.1 on software and hardware.We are very proud of this product,it combines great power with a tiny footprint and is easy to use.The highest output pulse per axis is 500KHz. This provides high control precision for stepper motors and servo motors.The DDCS numerical control system adopts the ARM+FPGA design framework. The ARM can finish the part of human-computer interface and code analysis and the FPGA can finish the part of underlying algorithm and control pulse generate, with the reasonable design, reliable control and easy operation. Reliable control and easy operation.The internal operating system is Linux based. The panel layout structure of the DDCS V3.1 is very rational to save space. All operations are controlled by only 17 keys and a comprehensive G code set is supported. The DDCS can be used for many styles and types of CNC machines. Lathes, Routers, Pick and Place and Mills are just a few examples. The DDCS operates as a Stand Alone system without the need of a computer. With high precision, accuracy and reliability. The interface, even very comprehensive, can be learned in a very short time.DDCSV3.1 is the 4 axis motion controller.The control period of each position is only 4 milliseconds, with a high control precision. The highest uniaxial output pulse is 500KHz and the pulse width can be adjusted. It supports the common stepper motor and servo motor.The panel layout structure of DDCSV3.1 is rational. The CNC MOTION SYSTEM Controller can be finished only by 17 keys and it supports the FANUC with high universality to be compatible with G code set.

DDCS V3.1 Brief technical feature:

1) 16 photoelectric isolated digital inputs,3 photoelectric isolated digital outputs;2) 3.1 Version enhenced Algorithm,support soft interpolation,fixed arc interpolation bug of the old version;3) Analog spindle control 0-10V spindle control (can be modified as PWM output);4) 3-4 axis motor Control.Differential Pulse and direction output signal,Max.500Khz per axis;5) ARM9 main control chip,FPGA core algorithm chip;6) 5 inches TFT screen, resolution ratio: 480×272,17 operation keys;7) The Power Supply for the controller is 24VDC, minimum Current is 0.5A;8) The Power Supply for IO Port is 24VDC,minimum current is 0.5A;By the IO power supply,system already supply the power for IO ports.So no need the external power supply for IO port anymore;9) USB flash disk support for G code file input,no size limited of the G-code file ;10) Support standard MPG;11) Jog function for each axis (continuous, step, defined distance);Customer can define the distance;12) Support the operation of quickly specify the running position;13) Support for “Power Cut” recovery. Data is automatically saved;14) The controller only support NPN type limited switch.

The Limit wiring at X++ direction with mechanical limited switch

PIN6(YL++),PIN23(XL++),PIN25(YL–),PIN5(XL–),PIN28(AL–),PIN9(AL++),PIN8(ZL–),PIN26(ZL++) are the Limit ports.

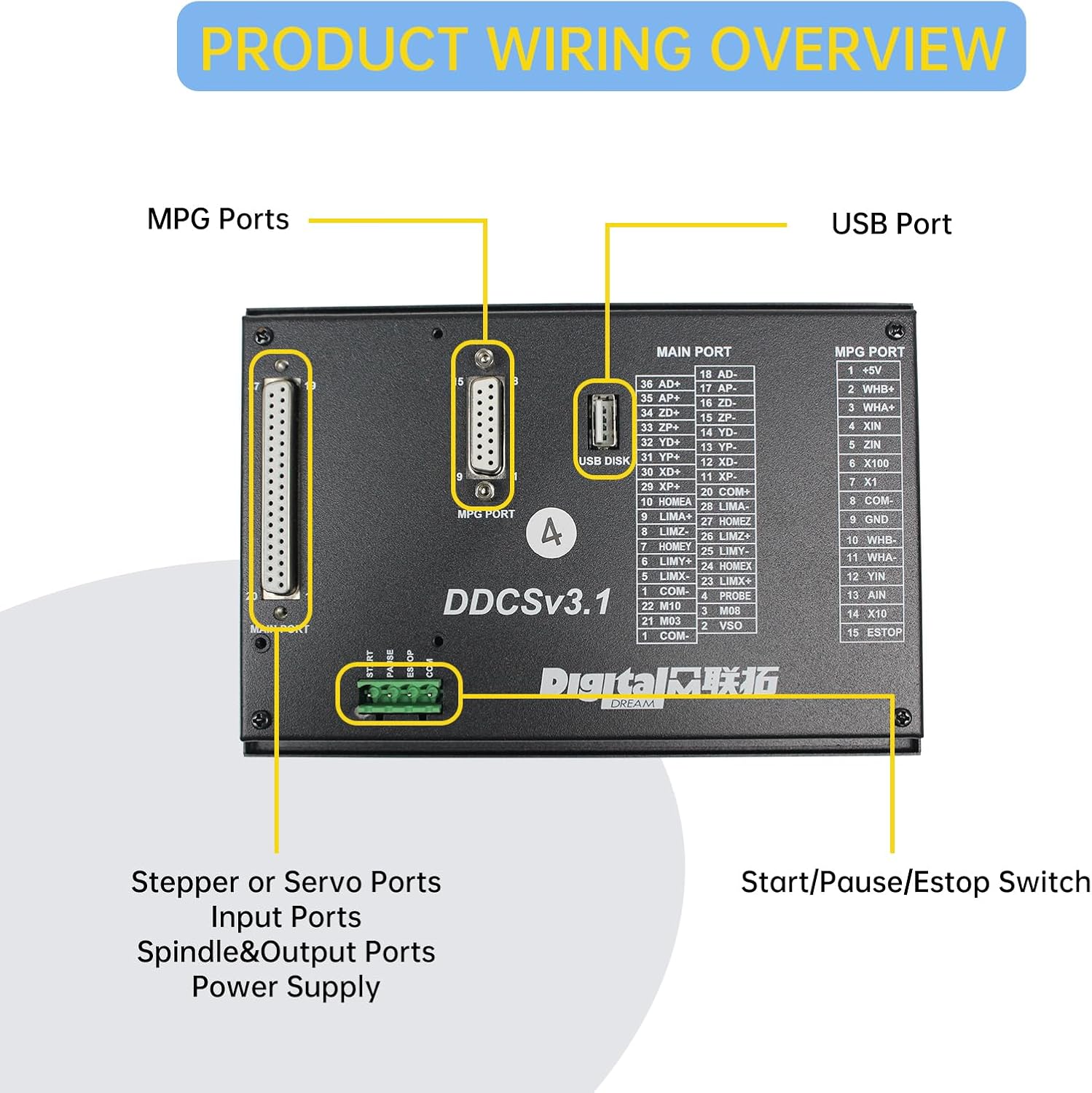

Power Supply Input

DDCS V3.1 needs two power supplies,Main power is for system,IO Port is for Input and Output ports. Both power supply is 24VDC,current is not less then 1A.In the Main port interface,the marked 24V and GND is the main power input ports;the COM+ and COM- is the IO power input ports.Only when the two power supplies are connected correctly the controller can be work properly.Becasue of the IO power,the controller system can supply power to all the IO ports,the IO ports is no need of the external power any more,for example,the relay.

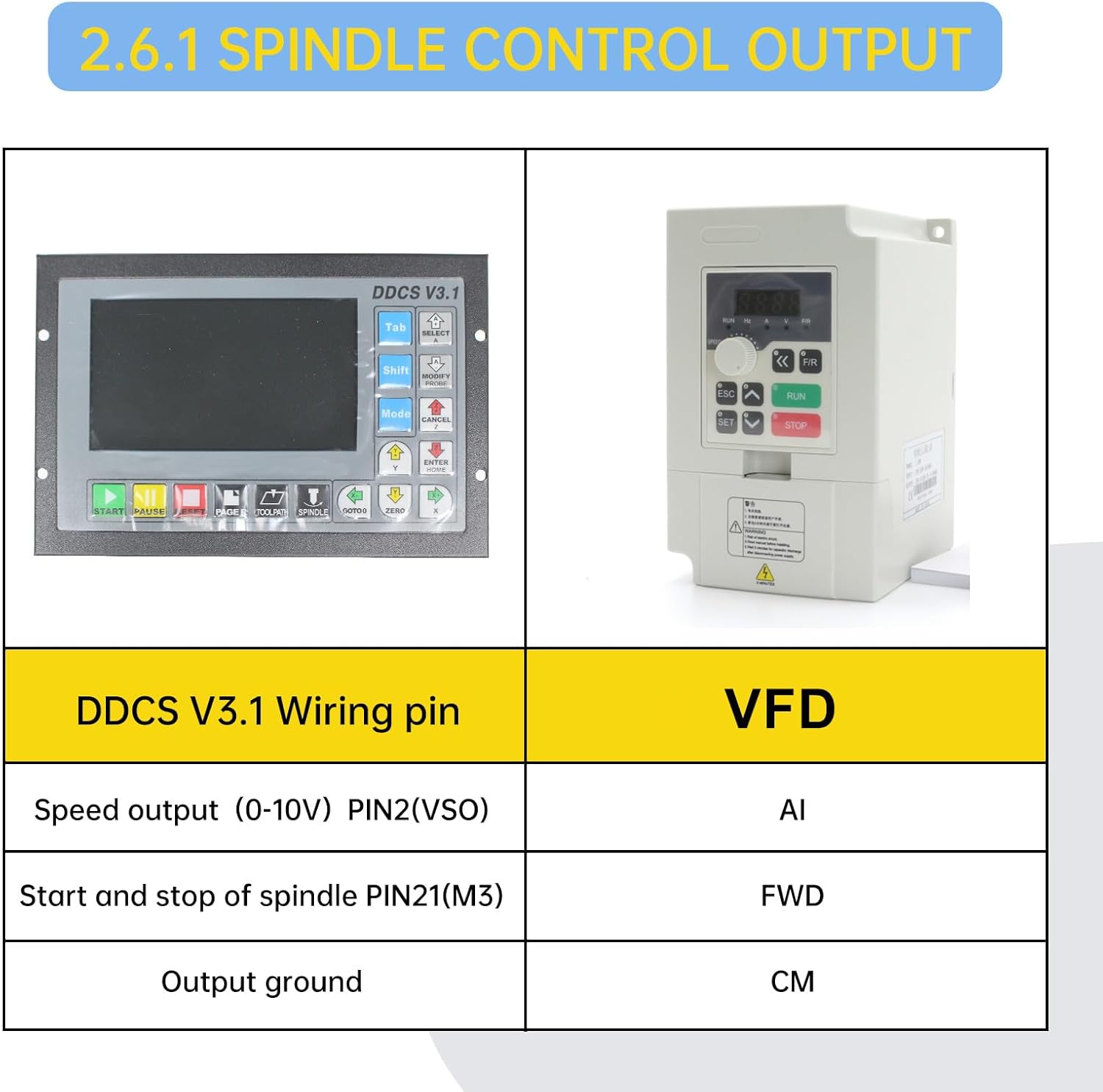

Spindle control output

PIN3(M8),PIN22(M10),PIN2(VSO) and PIN21(M3) is for spindle control output.The spindle control output terminal offers connections for Start and Stop of the Spindle (M3/M5), Start/Stop of Cooling (M8/M9) and Start/Stop of Lubrication (M10/M11). These three output terminals are signals open to ground. The highest electric current can be absorbed is 50mA. The speed controlling output terminal can output 0-10V. It can adjust the speed of the spindle motor by sending the voltage between 0 and 10V to the VFD according the the Spindle Speed Setting.Controlling the speed of a spindle with a VFD (variable frequency drive) only needs the Start/Stop signal and the 0-10V signal to control the frequency.PIN3(M8),PIN22(M10) and PIN21(M3) is also can be used for OUTPUT ports.For example,it can be used for a Relay output port.

Stepper/Servo Control Output

AD- means the Direction signal – output for A axisAD+ means the Direction signal + output for A axisAP- means the Pulse signal – outputAP+ means the Pluse Signal + output.The Pulse and Direction signal output voltage is ±5V. PIN 18(AD-),PIN 36 (AD+),PIN 17 (AP-),PIN 35 (AP+) is A Axis Control Output Pins;PIN 16 (ZD-),PIN 34 (ZD+),PIN 15 (ZP-),PIN 33 (ZP+) is Z Axis Control Output Pins;PIN 14 (YD-),PIN 32 (YD+),PIN 13 (YP-),PIN 31 (YP+) is Y Axis Control Output Pins;PIN 12 (XD-),PIN 30 (XD+),PIN 11 (XP-),PIN 29 (XP+) is X Axis Control Output Pins.

The Limit wiring at X++ direction with 3-line proximity switch

Limit wiring method for X++direction of 3-wire proximity switch.

The Probe Wiring

PIN10(AHOME),PIN27(ZHOME),PIN7(YHOME),PIN24(XHOME) are the Home Ports.PIN4(PROBE) is the Probe Port

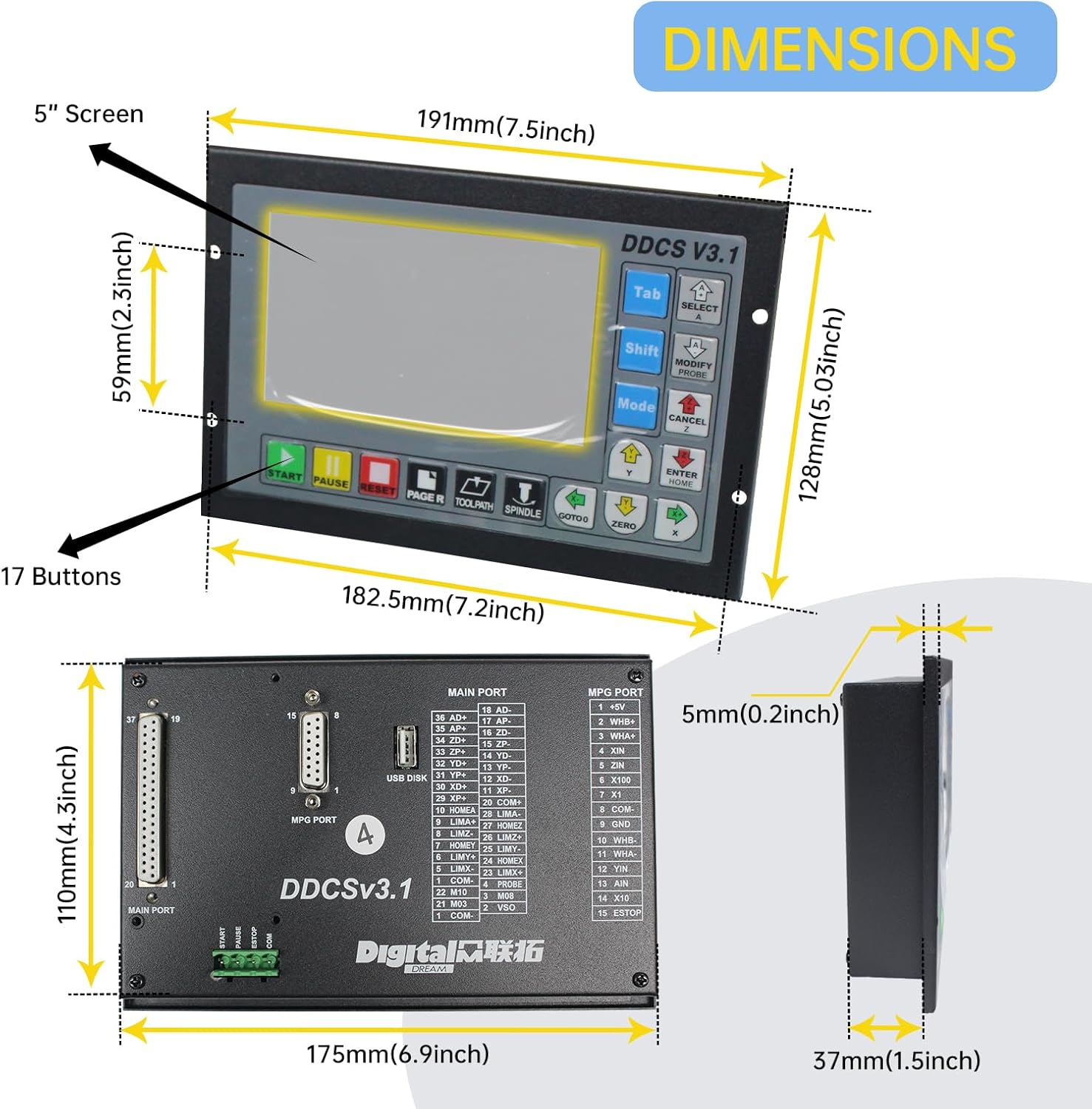

Outward Appearance,Structure and Size

The DDCS V3.1 is a small box that can fit in a window of a small control box or control cabinet.To mount the unit in an equipment c abinet, cut the hole182.5mm*59mmThe front of the product is 17 user keys and 4.3″ and 480*272 LSD (Liquid Crystal Display), and the reverse side is input signal, spindle control, stepper/ servo control, MPG and other four sets of interfaces as well as USB interface and power interface.The front panel is 191mm*128mm*5mmThe main body is 191mm*128mm*37mmThe back panel is 175mm*110mmControl System Unit is compatible with Metric Units and Imperial Units;MPG and extended Keyboard can also control and edit the controller system3 kinds Probing Modes:Fixed Position of tool sensor,Floating Position of the toolAdded a lot of parameters,Optimal Design and algorithmCited the new circuit design and metal box,which can avoid the noise a lot

4 Axis MPG Pendant Handwheel with Emergency stop with 15-pin plug

The CNC 4 Axis handheld controller MPG Pendant with x1, x10, x100 selectable, You are bidding one complete unit of the MPG pendant with Emergency stop for 4 axis CNC machine,it equipped with our popular machined MPG unit with 4 axis and scale selector, LED indicator also send feedback from the CNC machine to user about the status of the unit.

Plug and play, this MPG comes with a 15-pin plug, which can be directly connected to the 15-pin socket of the controller MPG.

x1, x10, x100 switchX,Y,Z,4th axis selector switchLED indicatorWith Emergency stopHigh quality professional chassisExtendable high quality shielded cable cordMagnetic base holder can place anywhere on the machine steel surfaceRequired 5V+, 150mA, power for MPGResolution:100PPRSupply Current:≤80mAOutput Voltage:≥2.5V and ≤0.4VFall/Rise time:≤5ns(typ)Response Frequency:0-10KHz

♞【Brief introduction】The DDCSV3.1 is a 4 axis motion controller,the highest output pulse per axis is 500KHz.This provides high control precision for stepper motors and servo motors.The DDCS operates as a stand alone system without the need of a computer, and it needs two 24V DC power supplies.

♞【Compatible with G code set】5 inches TFT Screen ; Resolution ratio: 480×272 ; the highest output pulse per axis is 500KHz. This provides high control precision for stepper motors and servo motors. All operations are controlled by only 17 keys and it supports the FANUC with high universality to be compatible with G code set,with 4G USB flash disk support for G code file input,no size limited of the G-code file.

♞【Brief technical feature】16 photoelectric isolated digital inputs,3 photoelectric isolated digital outputs ; Analog spindle control 0-10V spindle control (can be modified as PWM output) ; ARM9 main control chip,FPGA core algorithm chip ; Jog function for each axis (continuous, step, defined distance) ; Customer can define the distance ; Support NPN type limited switch.

♞【MPG Handwheel】MPG Resolution:100 PPR ; Switch:X1,X10,X100,with Emergency stop,LED indicator, with 15-pin plug,so it’s play and plug.

♞【Applications】The DDCV3.1 can be used for many styles and types of CNC machines. Lathes, CNC Routers,Pick&Place and Milling Machine,lathe machine and cutters are just a few examples.

Customers say

Customers like the quality of the controller. For example, they say it’s a good device and does exactly what it’d be expected to do. That said, opinions are mixed on the ease of installation.

AI-generated from the text of customer reviews

User Reviews

Be the first to review “CNCTOPBAOS 4 Axis Offline Stand Alone CNC Motion Controller System DDCSV3.1,Servo/Stepper Motor Control Replace Mach3 PLC+100PPR MPG Handwheel with E-Stop for CNC Router Engraving Machine”

$295.00

There are no reviews yet.